How fuel and oil spills affect your drainage systems and what to do about it.

Fuel and oil spills aren’t just an environmental hazard – they can seriously damage your drainage systems, compromise compliance and result in hefty clean-up costs or regulatory fines. Whether you’re operating a construction site, fuel depot, transport yard or industrial facility, understanding how these substances affect your drains, and what steps you can take to protect them, is essential for business continuity and environmental responsibility.

In this blog, we’ll explore how fuel and oil enter drainage systems, the impact they can have and the practical steps you can take to prevent, respond to and recover from spills.

How fuel and oil enter your drains.

Fuel and oil can enter your drainage network in a number of ways:

- Surface runoff – During rainfall, spilled oil or fuel on hardstanding surfaces (like tarmac or concrete yards) can be washed into gullies and interceptors.

- Leaks and overfills – From fuel tanks, delivery systems, generators or vehicles, especially in busy depots or during high-activity periods.

- Accidents and spillages – Operational incidents like hose failures, poor transfer practices or container mishandling can cause immediate drain contamination.

Many sites are connected to surface water drainage systems, which often discharge directly into local watercourses. Without adequate protection, a spill could pollute nearby streams, rivers or lakes and bring environmental scrutiny straight to your door.

The impact on drainage systems.

1. System blockages and backups.

Oil and fuel can coat the inside of your pipework, trapping debris and reducing flow. Over time, this can lead to blockages, flooding and property damage – especially if your interceptors or gullies are already poorly maintained.

2. Interceptor overload.

Fuel and oil separators (also known as interceptors) are designed to capture hydrocarbons before they enter the main drainage network. But when these systems are overwhelmed, either by volume or lack of maintenance, they lose effectiveness, allowing pollution to bypass the barrier.

3. Pipe corrosion and structural damage.

Petroleum-based substances can degrade some pipe materials over time, weakening joints or eroding seals. In extreme cases, this can lead to system failure or collapse.

4. Environmental contamination.

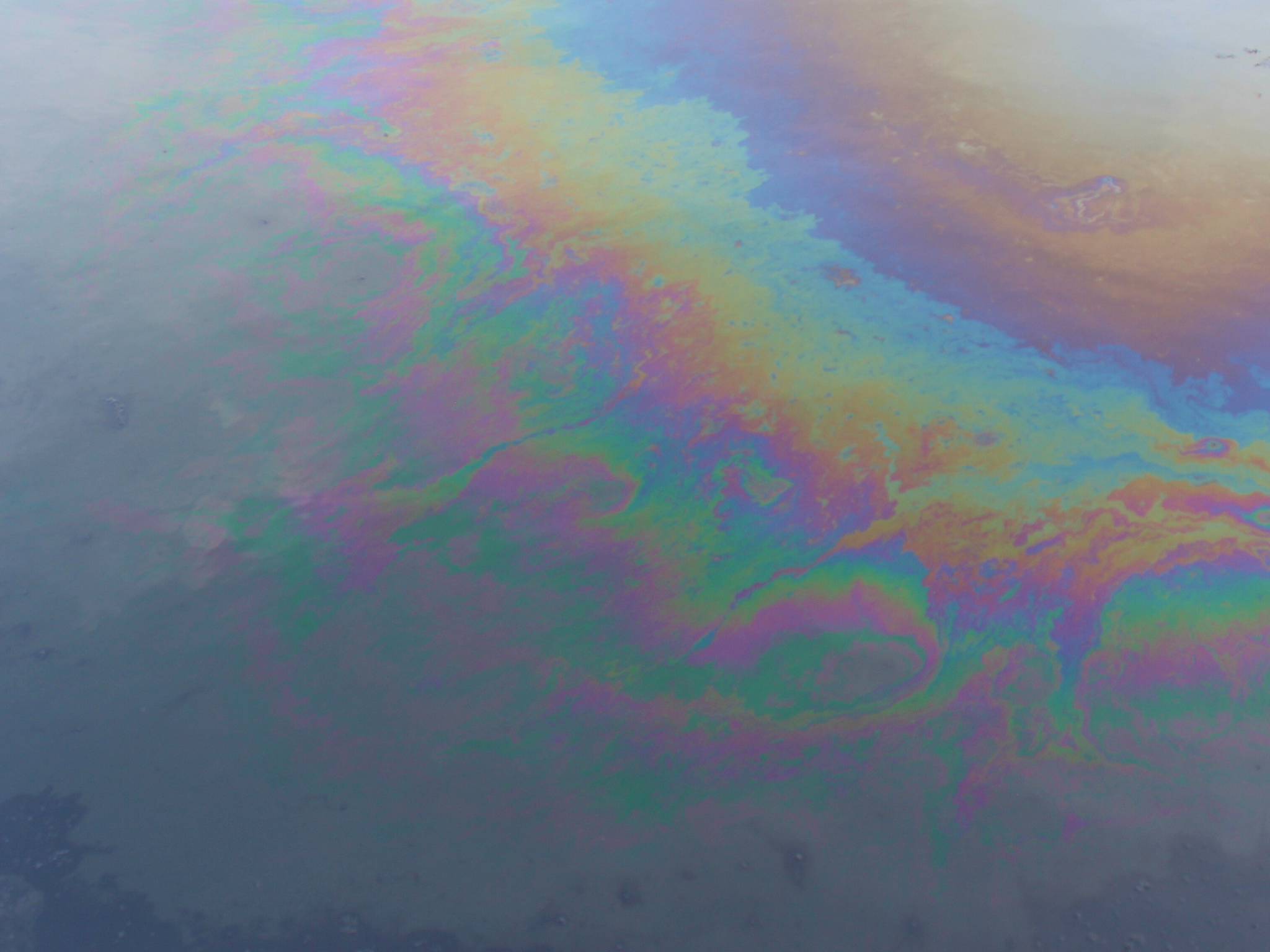

If contaminated water reaches a watercourse, the consequences can be immediate and severe. Oil films reduce oxygen transfer in water, harming aquatic life. The Environmental Agency has strict guidelines and penalties for polluting incidents, even if they’re unintentional.

5. Legal and financial consequences.

Failing to prevent or manage a spill can breach your environmental permits or planning conditions. Businesses may face prosecution, fines, clean-up costs and reputational damage, not to mention potential downtime during investigations or remedial works.

What to do if you have a fuel or oil spill.

Acting fast is key. Here’s what to do if fuel or oil enters your drainage system:

Contain the spill

- Use spill kits, booms or absorbent pads to stop the spread on surface areas.

- Prevent further flow into gullies or drainage channels where possible.

Stop the source

- Shut off any leaking machinery or transfer pumps.

- Isolate the affected area and notify your on-site safety or environmental officer.

Call the experts

- Contact a specialist drainage contractor like RSM who can carry out emergency callouts to assess and mitigate the damage.

- They’ll inspect and clean the drainage system, empty interceptors and ensure the site is safe and compliant.

Report the incident

- If pollution has entered a watercourse, report it immediately to the Environment Agency’s 24-hour incident hotline.

Review and improve

- After the incident, conduct a site review. What caused the spill? Could it have been prevented?

- Review your spill response plan and ensure your team is trained and equipped to act quickly in future.

How to prevent fuel and oil drain contamination.

Regular interceptor maintenance.

Ensure your oil separators are inspected and emptied regularly. RSM offers routine maintenance schedules to keep them performing at their best and compliant with PPG (Pollution Prevention Guidelines).

Gully and drain cleaning.

Blocked gullies or drainage lines increase the risk of overflow and contamination. Schedule periodic cleaning to keep your network flowing freely.

Site surveys and mapping.

Understanding how your drainage flows is vital. RSM’s drainage surveys and mapping services help identify high-risk areas and catch issues before they escalate.

Spill response plans.

Every high-risk site should have a documented spill response plan, clear signage and accessible kits for containment and clean-up.

How RSM Drain Solutions can help.

At RSM, we specialise in proactive and emergency drainage solutions to help you manage the risks associated with fuel and oil spills. Our services include:

- Emergency call-outs for spill response

- Fuel interceptor cleaning and maintenance

- Drain unblocking, jetting and CCTV inspections

- Full drain system surveys and compliance checks

- Long-term maintenance plans tailored to your site

With decades of experience and a rapid nationwide response team, we help businesses across the UK stay compliant, avoid costly incidents and protect their people, property and the planet.

Take action before it becomes a problem.

Fuel and oil spills are a real risk, but they don’t have to become a disaster. With proper maintenance, planning and the right drain solutions partner, you can keep your drainage system running smoothly and your site compliant.

Worried about how a spill might affect your drainage system? Visit our Drain Solutions page to find out how we can protect your site and respond when it matters most.